Peculiarities in the design and construction of photovoltaic-PV plants

Turkey is well-placed to benefit from the successful development of the solar energy industry. I hope that this article will encourage project developers and financiers in Turkey to adopt industry best practices in the development, construction, operation and financing of solar projects.

Solar PV Technology

The applications of solar PV power systems can be split into four main categories:

Off - grid domestic

Off - grid non-domestic

Grid -connected distributed

Grid -connected centralized

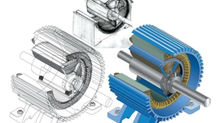

The main components of a PV power plant are PV modules, mounting (or tracking) systems, inverters, transformers and the grid connection. Solar PV modules are made up of PV cells, which are most commonly manufactured from silicon but other materials are available. PV modules must be mounted on a structure. This helps to keep them oriented in the correct direction and provides them with structural support and protection.

Mounting structures may be either fixed or tracking. Since fixed tilt mounting systems are simpler, cheaper and have lower maintenance requirements than tracking systems, they are the preferred option for countries with a nascent solar market and with limited indigenous manufacturers of tracking technology. Although tracking systems are more expensive and more complex, they can be cost-effective in locations with a high proportion of direct irradiation.

PV modules are generally connected together in series to produce strings of modules of a higher voltage. These strings may then be connected together in parallel to produce a higher current DC input to the inverters. Inverters are solid state electronic devices that convert DC electricity generated by the PV modules into AC electricity, suitable for supply to the grid. In addition, inverters can also perform a range of functions to maximize the output of a PV plant.

In general, there are two main classes of inverters: central inverters and string inverters. Central inverters are connected to a number of parallel strings of modules. String inverters are connected to one or more series strings. While numerous string inverters are required for a large plant, individual inverters are smaller and more easily maintained than a central inverter.

While central inverters remain the configuration of choice for most utility-scale PV projects, both configurations have their pros and cons. Central inverters offer high reliability and ease of installation. String inverters, on the other hand, are cheaper to manufacture, simpler to maintain and can give enhanced power plant performance on some sites.

Solar resource

A key parameter is the Performance ratio (PR) of a PV power plant, which quantifies the overall effect of losses on the rated output. The PR includes the array losses (Shadings, PV conversion, mismatch, wiring, etc) and the system losses (inverter efficiency in grid-connected, or storage/battery/unused losses in stand-alone, etc). The PR, usually expressed as a percentage, can be used to compare PV systems independent of size and solar resource. A PR varying from approximately 77% in summer to 82% in winter (with an annual average PR of 80%) would not be unusual for a well-designed solar PV installation or plant, depending on the ambient conditions.

It is also important to consider the capacity factor of a PV power plant. This factor (usually expressed as a percentage) is the ratio of the actual output over a period of a year to theoretical output if the plant had operated at nominal power for the entire year.

This apart, the “specific yield” (the total annual energy generated per kWp installed) is often used to help determine the financial value of a plant and compare operating results from different technologies and systems.

Reliable solar resource data are essential for the development of a solar PV project. While these data at a site can be defined in different ways, the Global Horizontal Irradiation (the total solar energy received on a unit area of horizontal surface) is generally of most interest to developers.

There are two main sources of solar resource data: satellite derived data and land-based measurement. Since both sources have particular merits, the choice will depend on the specific site. Land based site measurement can be used to calibrate resource data from other sources (satellites or meteorological stations) in order to improve accuracy and certainty.

Solar resource data are available from various sources. These include the Meteorological department, NASA’s Surface Meteorology and Solar Energy data set, METEONORM’s global climatological database, and satellite- derived geospatial solar data products from the United States national renewable Energy Laboratory. These sources are of varying quality and resolution. Appropriate expertise is needed to interpret the data.

Project Development

The development of a PV project can be broken down into the following phases: conceptual, pre-feasibility study, feasibility study, development and design. In general, each succeeding phase entails an increased level of expenditure but reduces the risk and uncertainty in the project. In practice, the progression through these phases is not strictly linear. The amount of time and money committed in each phase will vary, depending on the priorities and risk appetite of the developer.

A typical scope for a feasibility study would include the items below:

Production of a detailed site

Calculation of solar resource and environmental

Assessment of shading (horizon and nearby buildings and objects).

Outline layout of areas suitable for PV

Assessment of technology options providing cost/ benefit for the project location:

Module

Mounting

Outline system

Application for outline planning

Grid connection – more detailed assessment of likelihood, cost and

Predicted energy

Financial

The development phase takes the project from the feasibility stage through to financial close and is likely to consist of:

Preparation and submission of the permit applications for the proposed solar PV

Preparation and submission of a grid connection application.

Revision of the design and planning

Decision on contracting strategy (turnkey EPC contract or multi- contract).

Decision on the financing

Preparation of solar PV module tender

Supplier selection and

Preparation of construction tender

Contractor selection and

Contract

Completion of a bankable energy

Preparation of a financial model covering the full life cycle of the

Completion of a project risk

Environmental impact

Production of a detailed project repor

Securing financing for the project

The design phase will prepare the necessary detail and documentation to enable the tendering and construction of the solar PV plant.

Site selection

Selecting a suitable site is a crucial part of developing a viable solar PV project. In selecting a site, the aim is to maximize output and minimize cost. The main constraints that need to be assessed include:

Solar resource – Global Horizontal Irradiation, annual and inter-annual variation, impact of

Local climate – flooding, high winds, snow and extreme temperatur

Available area – area required for different module technologies, access requirements, pitch angle and minimizing inter-row

Land use – this will impact land cost and environmental The impact of other land users on the site should also be considered.

Topography – flat or slightly south facing slopes are preferable for projects in the northern

Geotechnical – including consideration of groundwater, resistivity, load bearing properties, soil pH levels and seismic

Geopolitical – sensitive military zones should be av

Accessibility – proximity to existing roads, extent of new roads

Grid connection – cost, timescales, capacity, proximity and av

Module soiling – including local weather, environmental, human and wildlife

Water availability – a reliable supply is required for module

Financial incentives – tariffs and other incentives vary between countries and regions within

Energy Yield prediction

The energy yield prediction provides the basis for calculating project revenue. The aim is to predict the average annual energy output for the lifetime of the proposed power plant (along with the confidence levels). The level of accuracy required will depend on the stage of development of the project.

To estimate accurately the energy produced from a PV power plant, information is needed on the solar resource and temperature conditions of the site. Also required are the layout and technical specifications of the plant components.

To make life easy for project developers, a number of solar energy yield prediction software packages are available in the market. These packages use time step simulation to model the performance of a project over the course of a year. To ensure more accurate results that would satisfy a financial institution’s due diligence and make the project bankable, the analysis should be carried out by a qualified expert. Realistic allowance should be made for undermining factors such as air pollution, grid downtime and electrical losses.

Plant design

The design of a PV plant involves a series of compromises aimed at achieving the lowest possible levelised cost of electricity. Choosing the correct technology (especially modules and inverters) is of central importance. Selecting a module requires assessment of a complex range of variables. At the very least, this assessment would include cost, power output, benefits / drawbacks of technology type, quality, spectral response, performance in low light, nominal power tolerance levels, degradation rate and warranty terms.

The factors to consider when selecting inverters include compatibility with module technology, compliance with grid code and other applicable regulations, inverter-based layout, reliability, system availability, serviceability, modularity, telemetry requirements, inverter locations, quality and cost.

In designing the site layout, the following aspects are important:

Choosing row spacing to reduce inter-row shading and associated shading losses.

Choosing the layout to minimize cable runs and associated electrical losses.

Allowing sufficient distance between rows to allow access for maintenance purposes.

Choosing a tilt angle that optimizes the annual energy yield according to the latitude of the site and the annual distribution of solar resource.

Orientating the modules to face a direction that yields the maximum annual revenue from power production. In the northern hemisphere, this will usually be true south.

The electrical design of a PV project can be split into the DC and AC systems. The DC system comprises the following:

Array(s) of PV modules.

Inverters.

DC cabling (module, string and main cable).

DC connectors (plugs and sockets).

Junction boxes/combiners.

Disconnects/switches.

Protection devices.

Earthing

The AC system includes:

AC cabling.

Switchgear.

Transformers.

Substation.

Earthing and surge protection.

Every aspect of both the DC and AC electrical systems should be scrutinised and optimized. The potential economic gains from such an analysis are much larger than the cost of carrying it out. In order to achieve a high performance PV plant, the incorporation of automatic data acquisition and monitoring technology is essential. This allows the yield of the plant to be monitored and compared with calculations made from solar irradiation data to raise warnings on a daily basis if there is a shortfall. Faults can then be detected and rectified before they have an appreciable effect on production

Permits and licensing

Permit and licensing requirements vary, depending on the location of the project but the key permits, licenses and agreements typically required for renewable energy projects include:

Land lease

Environmental impact

Building permit/planning consent.

Grid connection

Power purchase

The authorities, statutory bodies and stakeholders that should be consulted also vary from country to country but will usually include the following organization types:

Local and/or regional planning authority.

Environmental agencies/departments.

Archaeological agencies/departments.

Civil aviation authorities (if located near an airport).

Local communities.

Health and safety agencies/departments.

Electricity utilities.

Military authorities.

Early engagement with all relevant authorities is highly advisable to minimize risk and maximize the chances of successful and timely implementation of the project.

Construction

The management of the construction phase of a solar PV project should be in accordance with construction management best practice. The aim should be to construct the project to the required level of quality within the time and cost deadlines.

During construction, the environmental impact of the project as well as the health and safety issues of the workforce (and other affected people) should also be carefully managed. Compliance with these standards can facilitate the financing of a project.

Typical issues that arise during the construction of a PV project include:

Foundations not being suited to ground conditions.

Discovery of hazardous / contaminated substances during excavation.

Incorrect orientation of modules.

Insufficient cross-bracing on mounting structures.

Incorrect use of torque wrenches.

Damaging cables during construction / installation.

Delayed grid connection.

Access / construction constrained by weather.

Insufficient clearance between rows for vehicle access.

While some of these issues appear minor, rectification of the problems they cause can be expensive. While close supervision of contractors during construction is important, using the services of a suitably experienced engineer should be considered if the required expertise is not available in-house.

Commissioning

Commissioning should prove three main criteria:

The power plant is structurally and electrically safe.

The power plant is sufficiently robust (structurally and electrically) to operate for the specified project lifetime.

The power plant operates as designed and performs as expected.

Commissioning tests are normally split into three groups:

Visual acceptance tests. These tests take place before any systems are energized and consist of a detailed visual inspection of all significant aspects of the plant.

Pre-connection acceptance tests. These include an open circuit voltage test and short circuit current test. These tests must take place before grid connection.

Post-connection acceptance test. Once the plant is connected to the grid, a DC current test should be carried out. Thereafter, the performance ratio of the plant is measured and compared with the value stated in the contract. An availability test, usually over a period of 5 days, should also be carried out.

Operations and Maintenance

Compared to most other power generating technologies, PV plants have low maintenance and servicing requirements. However, suitable maintenance of a PV plant is essential to optimize energy yield and maximize the life of the system.

Maintenance consists of:

Scheduled or preventative maintenance – planned in advance and aimed to prevent faults from occurring, as well as to keep the plant operating at its optimum level.

Unscheduled maintenance – carried out in response to failures.

Scheduled maintenance typically includes:

Module cleaning.

Checking module connection integrity.

Checking junction / string combiner boxes.

Thermographic detection of faults.

Inverter servicing.

Inspecting mechanical integrity of mounting structures.

Vegetation control.

Routine balance of plant servicing / inspection. Common unscheduled maintenance requirements include:

Tightening cable connections that have loosened.

Replacing blown fuses.

Repairing lightning damage.

Repairing equipment damaged by intruders or during module cleaning.

Rectifying supervisory control and data acquisition (SCADA) faults.

Repairing mounting structure faults.

Rectifying tracking system faults.

Careful consideration should be given to selecting an operation and maintenance (O&M) contractor and drafting the O&M contract to ensure that the performance of the plant is optimized. After the project is commissioned, it is normal for the EPC contractor to guarantee the performance ratio and the O&M contractor to confirm the availability and, ideally, the performance ratio.

Economics and Financial Modeling

The development of solar PV projects can bring a range of economic costs and benefits at the local and national levels. Economic benefits can include:

Job creation.

Use of barren land.

Avoidance of carbon dioxide emissions.

Increased energy security.

Reduction of dependence on imports.

Increased tax revenue.

An awareness of the possible economic benefits and costs will aid developers and investors in making the case for developing solar energy projects to local communities and government bodies.

The financial benefits and drawbacks to the developer should be explored in detail through the development of a full financial model. This model should include the following inputs:

Capital costs – these should be broken down as far as possible. Initially, the prices should be included when possible.

Operations and maintenance costs – in addition to the predicted O&M contract price, operational expenditure will include comprehensive insurance, administration costs, salaries and labour wages.

Annual energy yield – as accurate an estimate as is available at the time.

Energy price – this can be fixed or variable and will depend on the location of the project as well as the tariff under which it has been developed.

Certified Emission Reductions – under the clean development mechanism, qualifying solar projects may generate Certified Emission reductions, which can then be sold. However, this revenue is difficult to predict.

Financing assumptions – including proportion of debt and equity, interest rates and debt terms.

Sensitivity analysis – sensitivity of the energy price to changes in the various input parameters should be assessed.

All rights of the producer and of the owner of the works reproduced reserved. Unauthorised copying, hiring, lending, public performance and broadcasting of this recording prohibited.

Kaynak:

Project Manager at PV-Systems I Ivan Ivanov